24/7 Workshop services

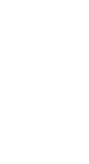

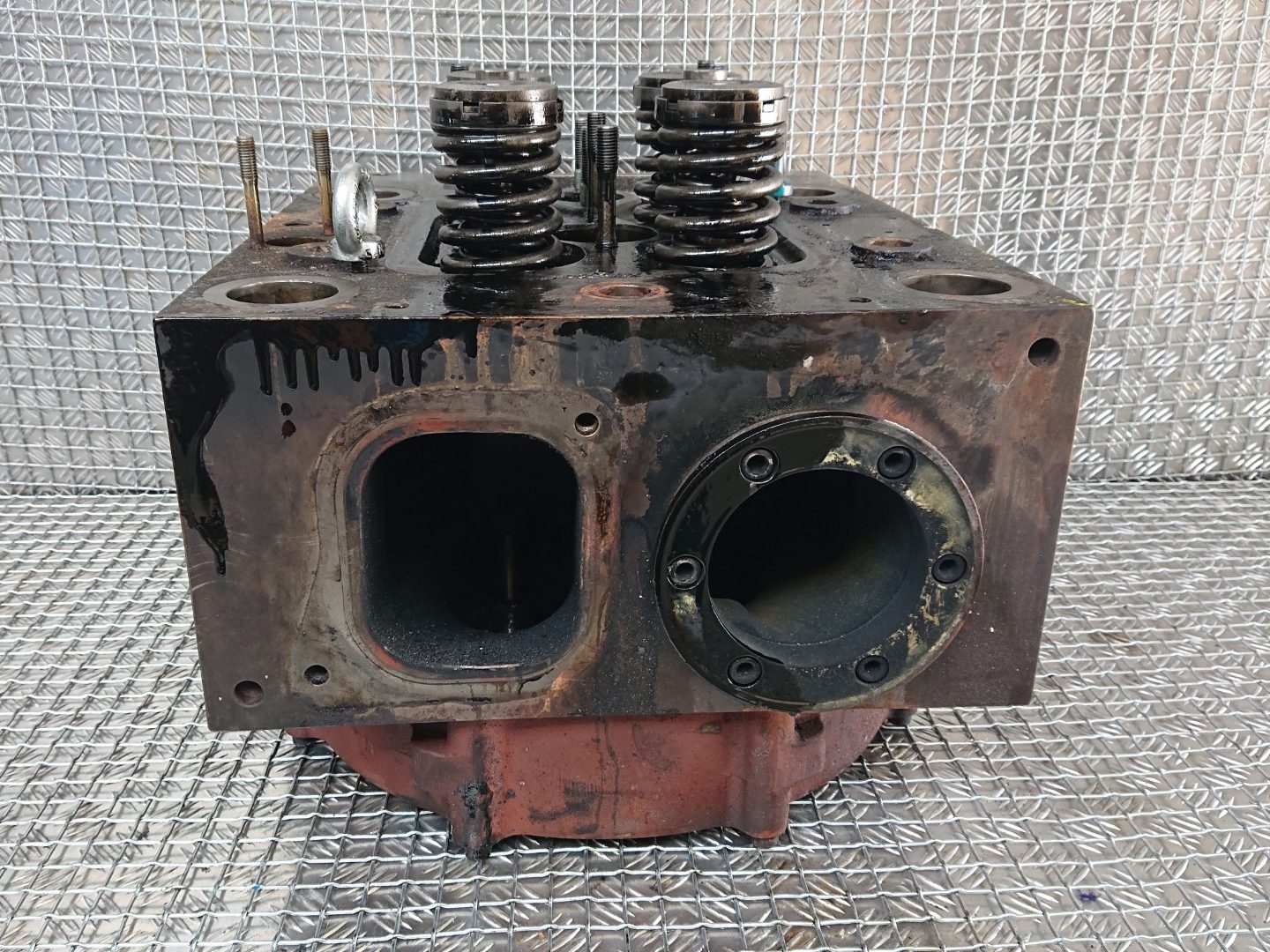

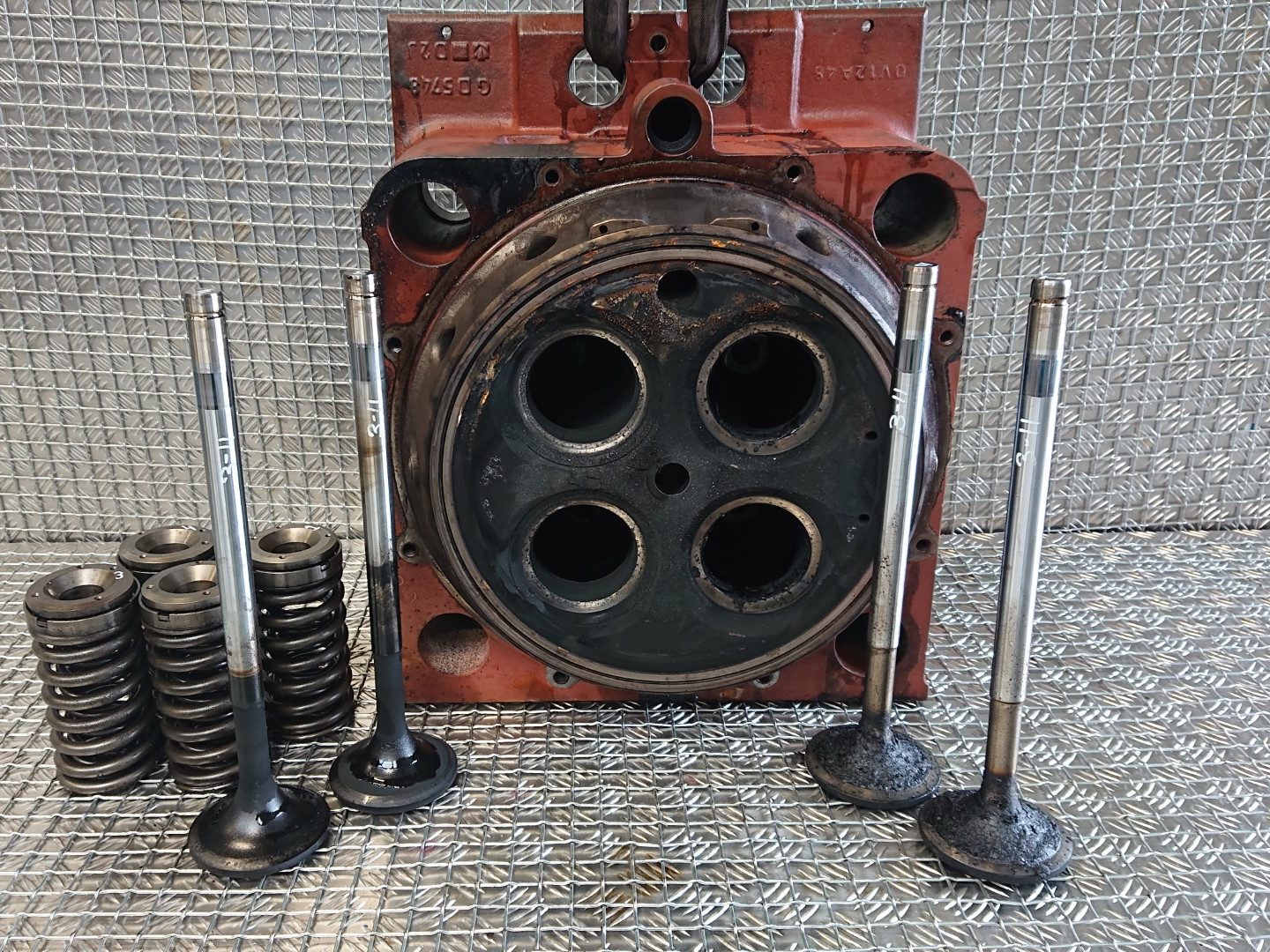

In our 1200 square meter workshop, that is well equipped with all the necessary tools and machinery to recondition, overhaul and repair any component of a main- or auxiliary marine engine, our team of mechanic and electrical engineers is ready 24/7.

Our mechanical workshop accommodates two overhead cranes with 10 tons lifting capacity each.

And recently we established a workshop, dedicated to electrical repairs and testing and calibrating of electrical components.

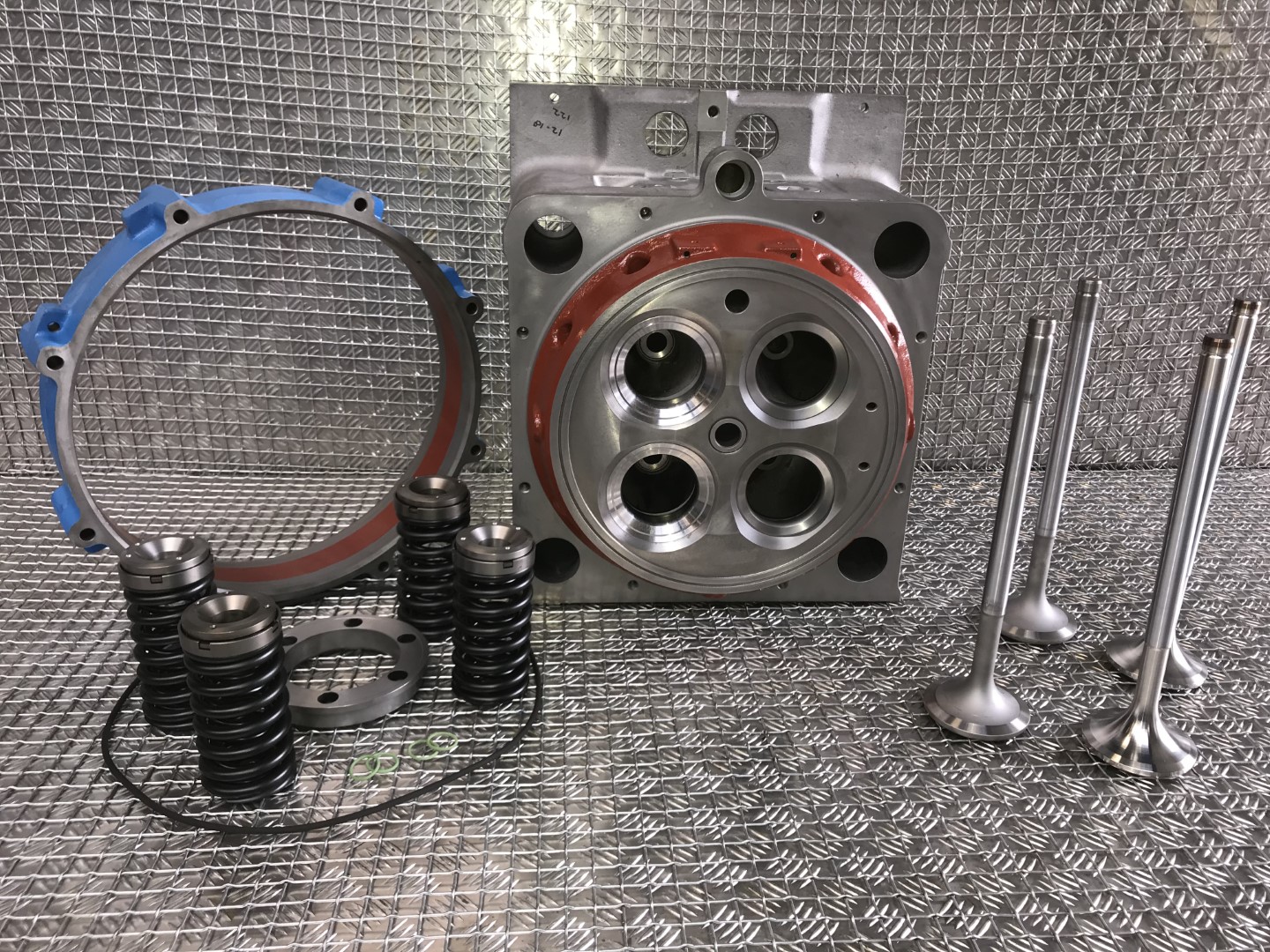

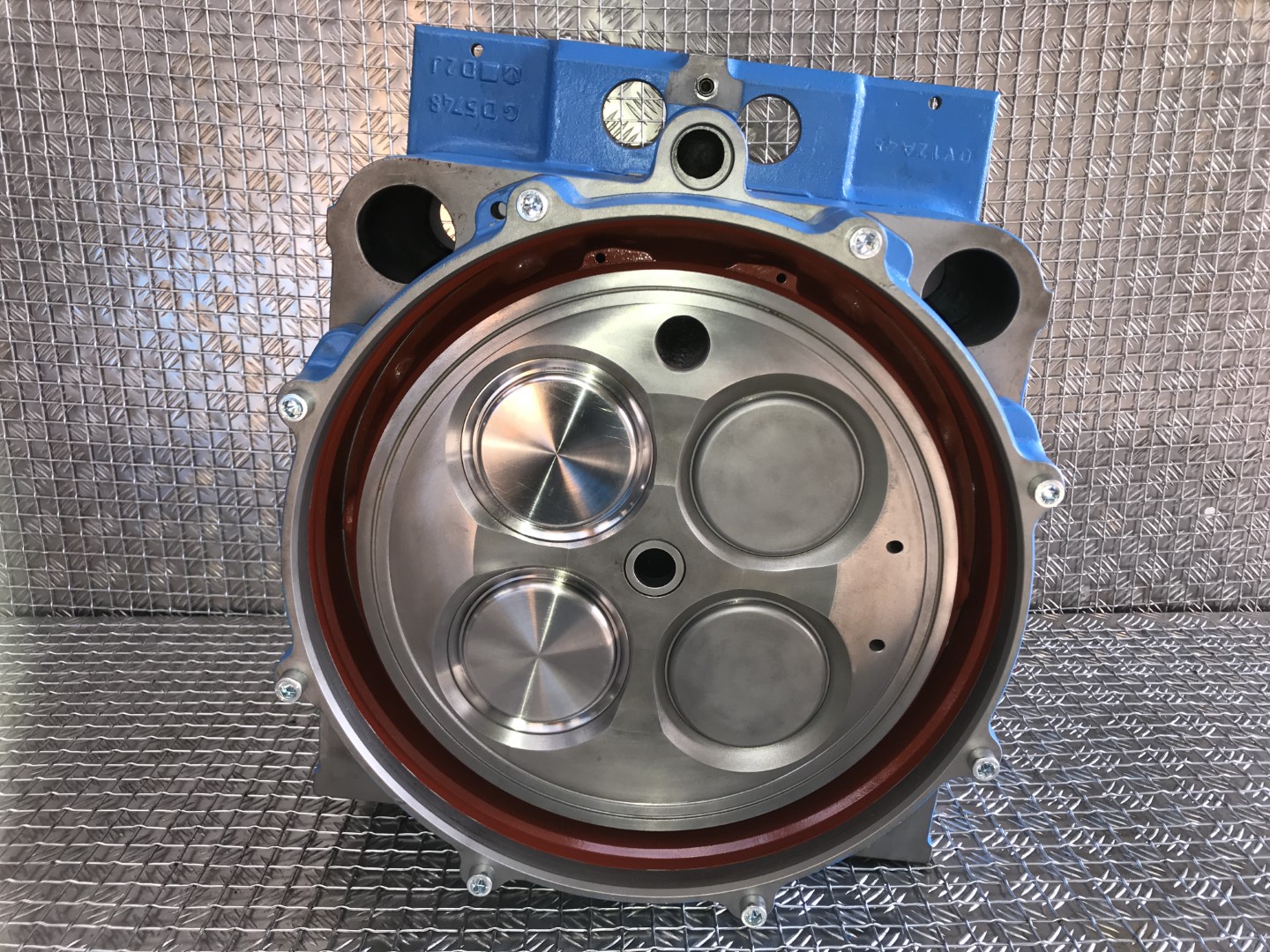

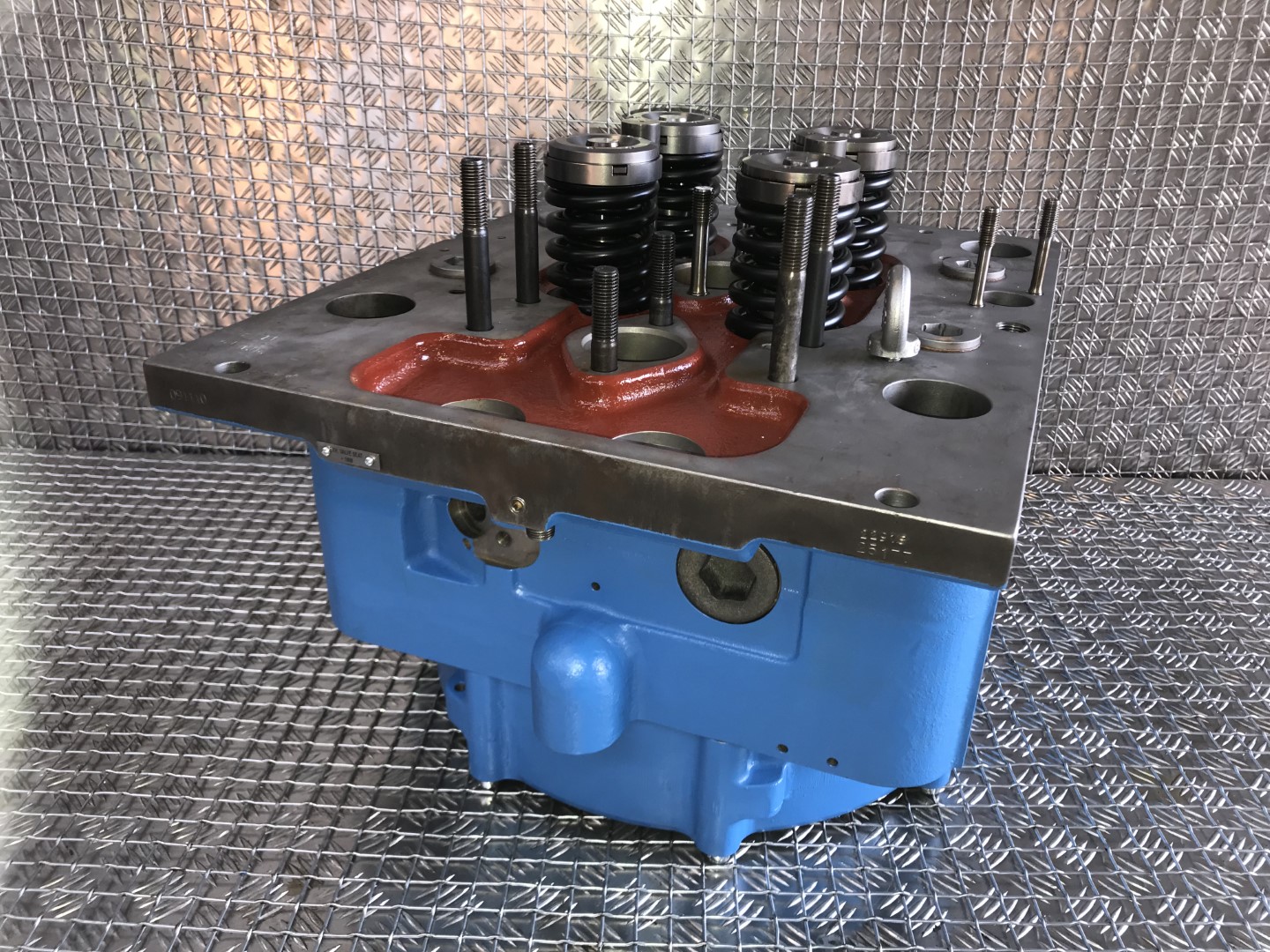

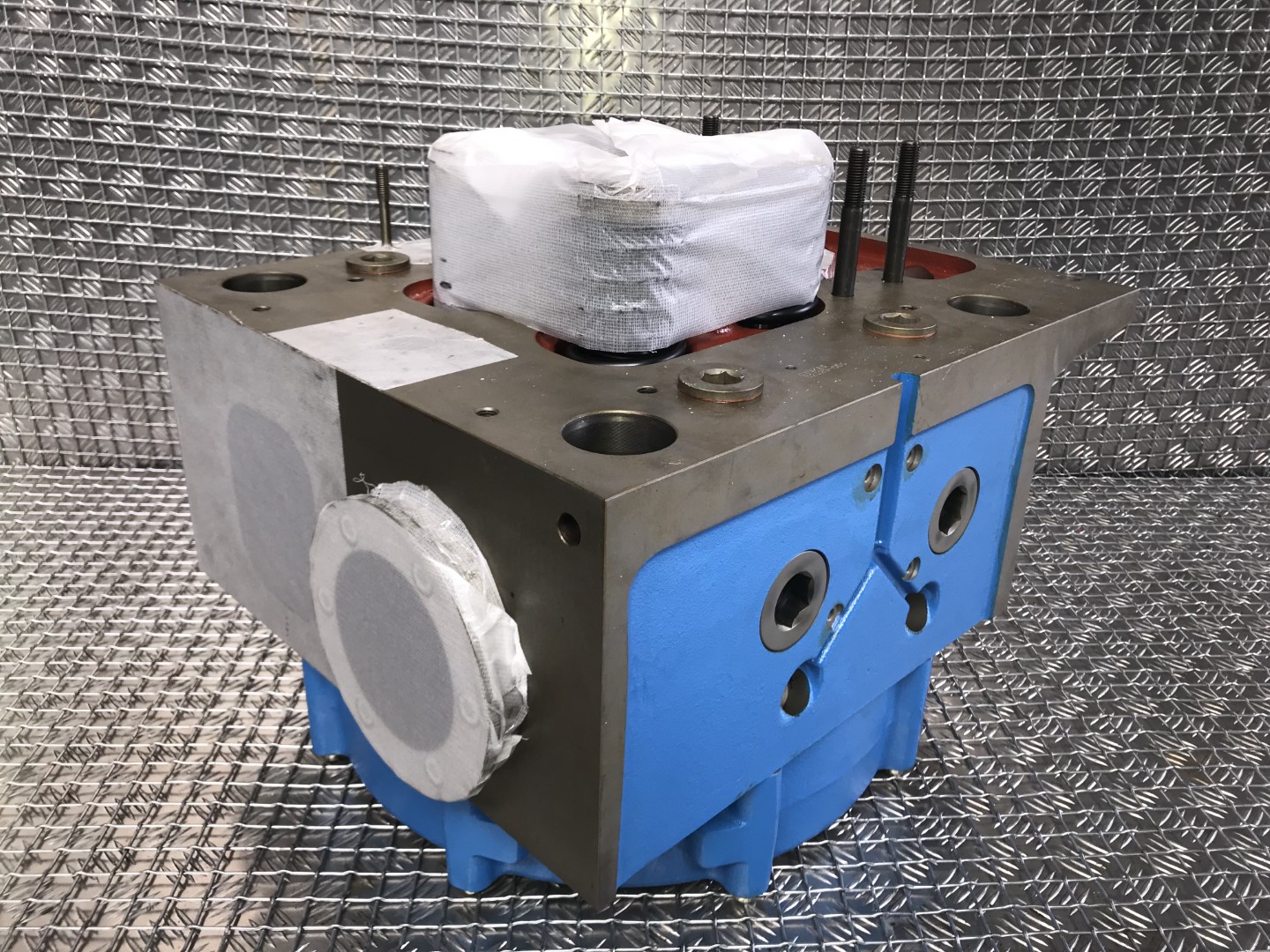

Our workshops are equipped to carry out following works:

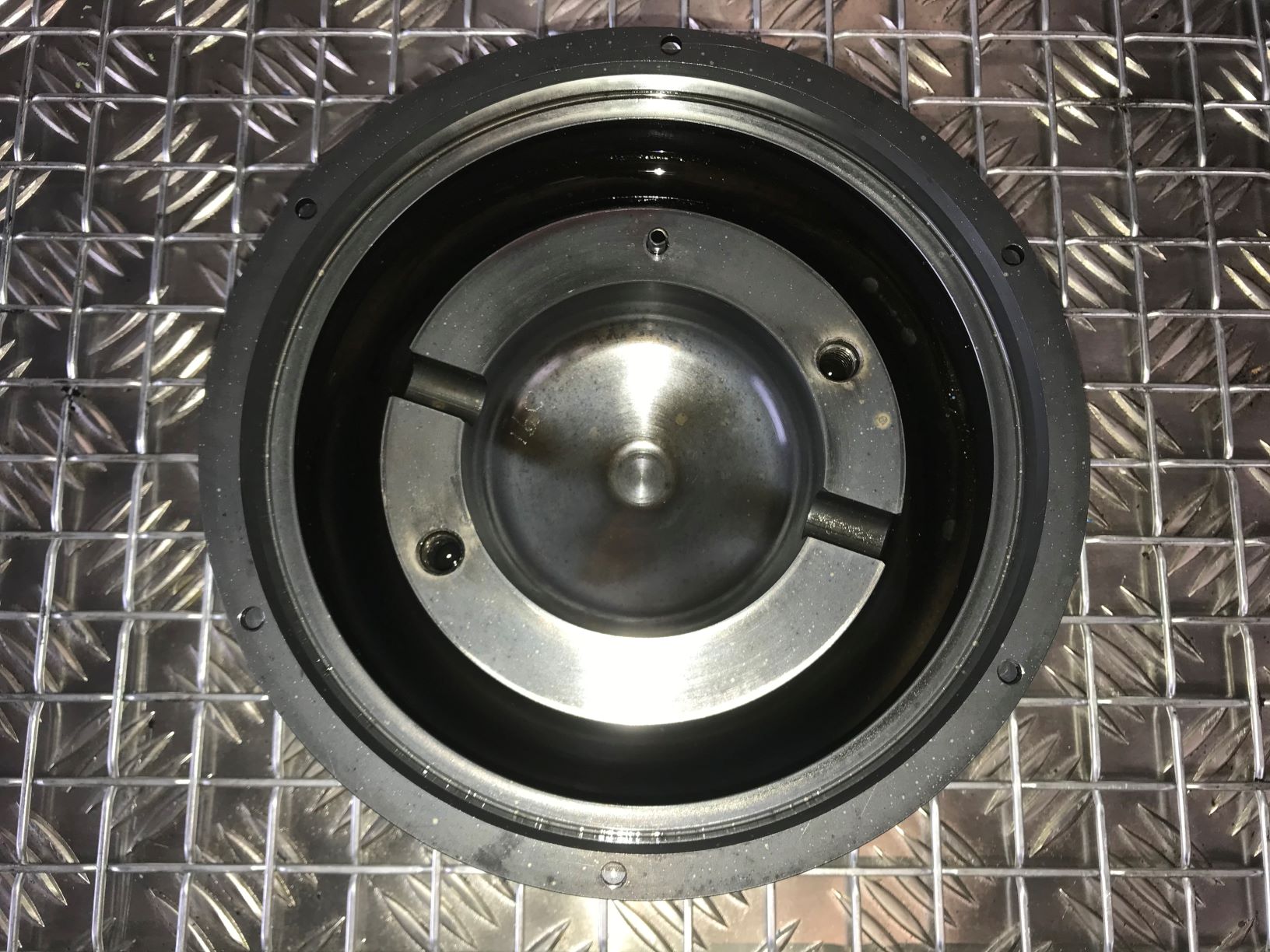

• Reconditioning and honing of cylinder liners with bore diameters of 100 mm till 1000 mm.

• Ultra-sonic cleaning of parts weighing up to 10,000 kg, 4.0 x 1.5 x 1.5 meters.

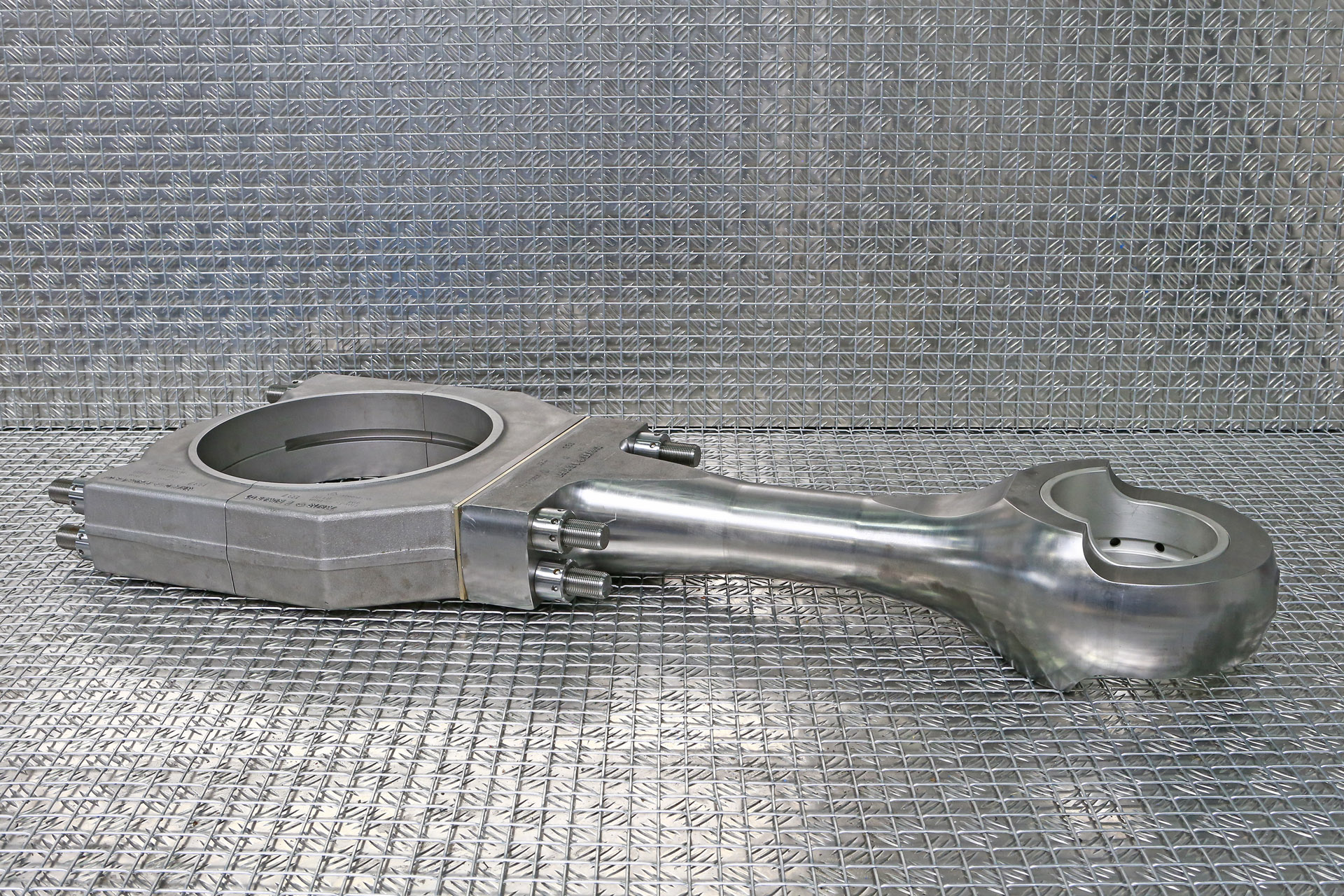

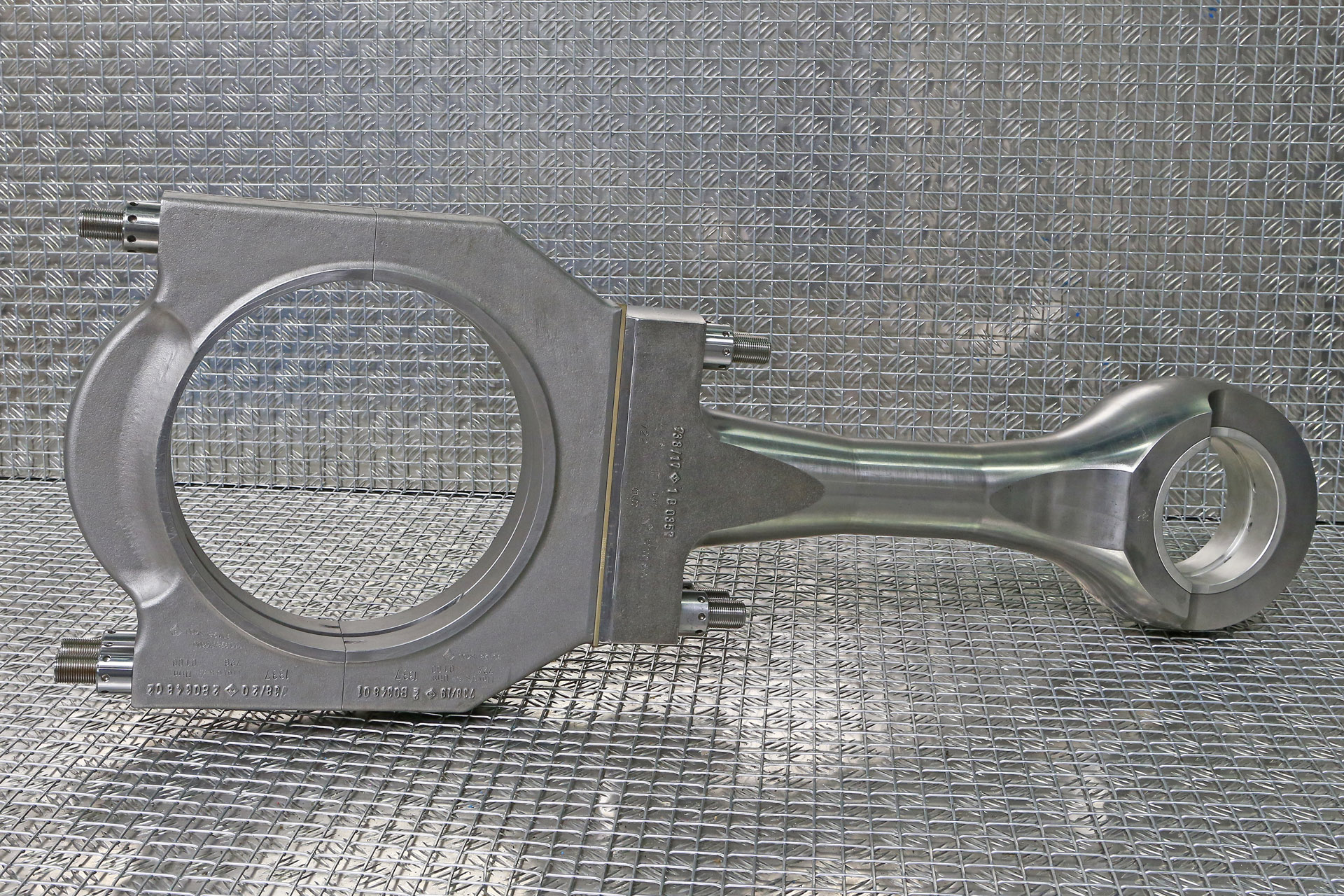

• Reconditioning of all kinds of connecting rods.

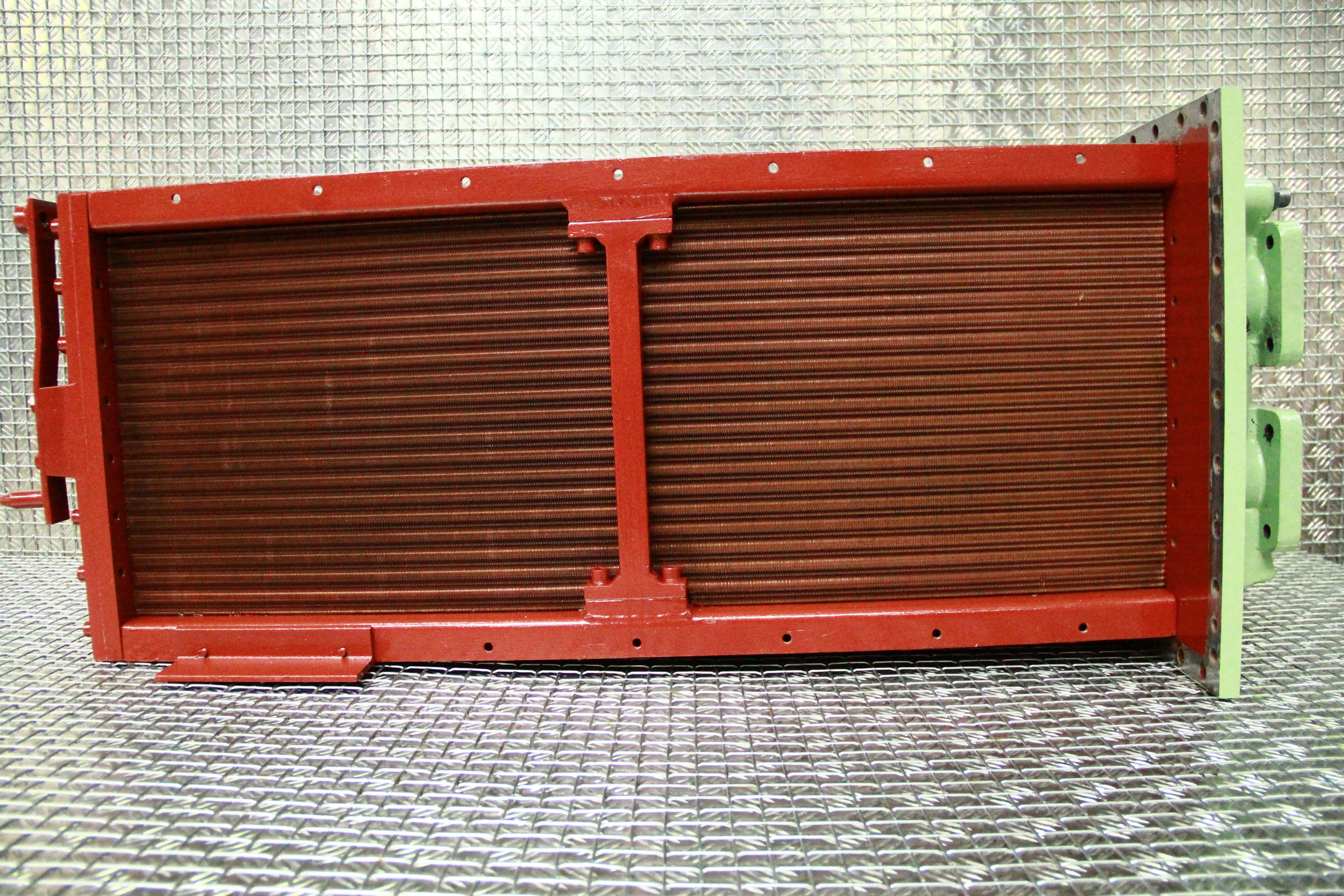

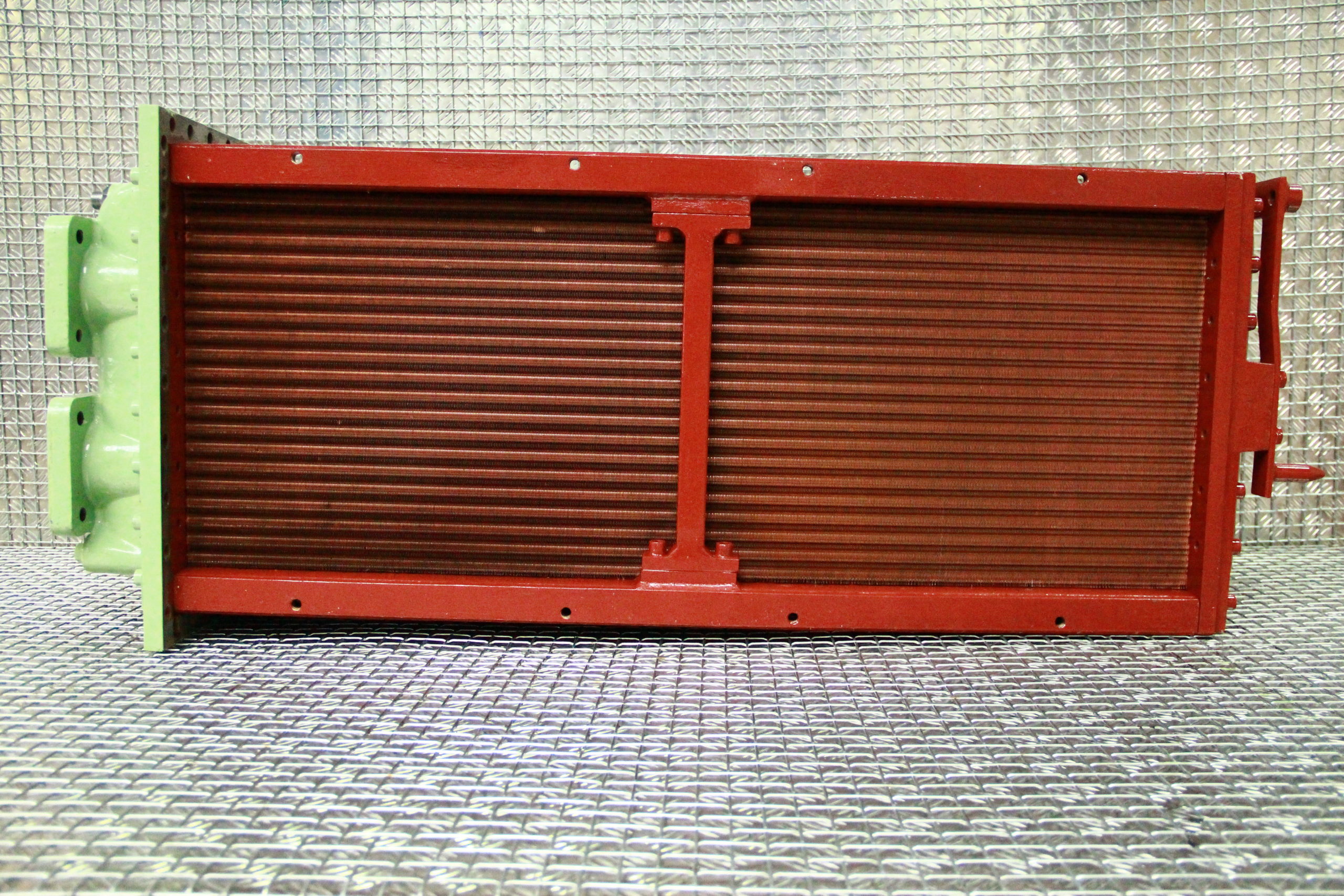

• Overhaul of air coolers.

• Overhaul of lubrication oil coolers.

• Reconditioning of fuel pumps and injectors for 2- and 4-stroke engines.

• Overhaul and reconditioning of governors.

• Reconditioning of all kinds of crankshafts and camshafts.

• Testing, calibration and modification of diesel engine- and control instruments.

• Maintenance and repair services to marine offshore and power plants

• All kind of steel works/pipe lines.